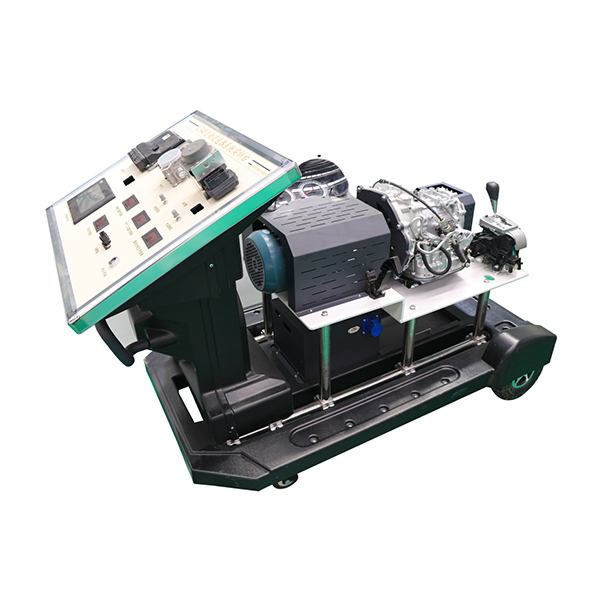

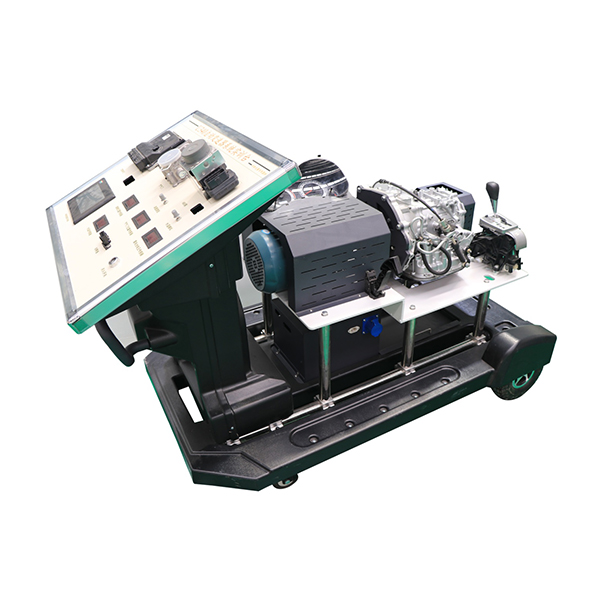

Type: BF-C-002

Volume: 1450MM×850MM×1180MM

Weight: 450KG

Power supply: 12V 50AH, 380V

Feature

1. Use Toyota U241E electronic control hydraulic transmission system to make; including: control unit, on-board network control unit, motor, etc.;

2. Use electric motor to simulate engine working conditions as power input;

3. The electronic control schematic diagram of the electronic control hydraulic system is distributed on the panel of the training platform, with measurement terminals on it, equipped with instrument panel, engine speed simulation device, electronic control unit ECU and OBDII diagnostic interface.

4. Use the numeric keyboard fault setting system. Touch-type fault simulation display screen, select and click to complete the fault setting;

5. The test bench adopts a movable support, profile welding, and the surface is sprayed with plastic.

6. Power supply: 220V, 50Hz, three-phase. Motor power: 350W.

7. Equipped with a tablet computer, which is installed on the training platform of the electronically controlled hydraulic power steering system. The tablet computer is installed with Toyota A340E system teaching and structure software. The training platform controls and controls the principle teaching of the electronically controlled hydraulic power system to run synchronously with the structural software. The working principle and working process of the transmission can be clearly observed on the software interface.

8. Teaching and structure software for electronically controlled hydraulic power system. ① Establish an electronically controlled hydraulic power system model in a 3D virtual reality environment. ②When the input speed changes, the software will synchronously display the internal operation of the transmission to realize the interactive work between the training platform and the software; ③Learn the structure and disassembly process of the electronically controlled hydraulic system.

Training Contents

1.Disassembly and assembly of U241E automatic transmission;

2.Analysis of the working principle of automatic shifting;

3.Electronic control system sensor and actuator diagnosis;

4.Reading and analysis of dynamic data streams;

5.Detection and analysis of sensors and actuators;

6.Fault simulation and detection under various working conditions

Reviews

There are no reviews yet.