Type: HKZMDJX

Motor model: M3P4H523

Power: 2.2KW

Speed: 1420r/min

Oil pump model: VAI-15F-A3

Rated pressure: 7Mpa Rated flow: 8ml/rev

Dimensions: 1550×650×1800mm

Feature

Hydraulic reach stacker is a kind of machinery used for container loading and unloading. It is widely used in port, railway and highway transportation operations. At present, almost all small and medium-sized reach stackers adopt hydraulic transmission. The hydraulic reach stacker has the advantages of small size, light weight, flexible and convenient operation, large lifting force, and easy realization of overload protection and indoor operation. In recent years, the application of high-tech microelectronics technology in hydraulic technology has made the comprehensive technical level of construction machinery, construction machinery and transportation machinery higher and higher, and improved the reliability, operational safety, comfort and service life of these machinery. More adaptable.

1. The test bench is made of cold-rolled steel plate (with plastic spraying and anti-corrosion treatment), and has a desktop structure and integrated control operation.

2. The electrical operation control is under-mounted, and the hydraulic station is placed in the main cabinet of the hydraulic table. The overall structure is compact and coordinated, the layout is beautiful and generous, and the practicability is strong, and it can be used for 4-6 people to experiment.

3. The full metal structure of the reach stacker machine is reduced in proportion to the actual object. During the experiment, the hydraulic system is activated to operate the machine according to the experimental requirements.

4. The reach stacker machine is made according to the actual structure and reduced scale, which can truly reflect the actual working conditions of the machine, so that students can deeply understand the structure and working principle of each part of the machine in the experiment.

5. Experimental control adopts manual control and automatic control.

6. The experimental parts adopt pressure-resistant hoses, and the pressure can reach 25Mpa.

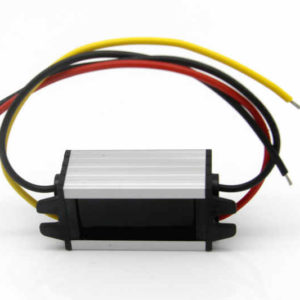

7. With three-phase leakage protection, the output voltage is 380V/220V, the power supply will be cut off when the leakage current to the ground exceeds 30mA; the electrical control adopts DC 24V power supply, and with overvoltage protection to prevent misoperation from damaging the equipment.

Training Contents

1. Demonstration control experiment of reach stacker machinery

1) For snatch operations, the snatch beam is positioned according to the length of the container;

1) For lifting operations, the main boom and the telescopic boom are combined for work experiments;

2) Swivel operation, lifting the beam while lifting the platform while the platform is rotating; (with motor rotating platform)

3) Obstacle operation, when the main boom and the telescopic boom are combined work, the servo cylinder on the top of the telescopic boom or the four obstacle detection cylinders distributed at the four corners of the grab beam will give the main system a stop or descend command (optional) when it encounters an obstacle;

4) Return, the platform rotates, the main boom and the telescopic boom cooperate to return to the initial position.

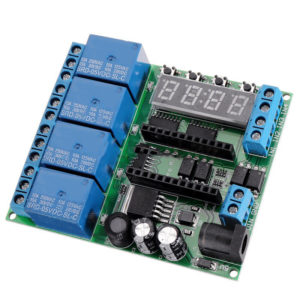

2. Programmable controller (PLC) electrical control experiment: machine-electric-hydraulic integrated control experiment.

1) PLC instruction programming, ladder diagram programming learning;

2) Learning and using PLC programming software;

3) Communication and online debugging between PLC and computer;

4) The application of PLC in hydraulic drive control and the optimization of control schemes.

Reviews

There are no reviews yet.